AOGONG VALVE

All greatness comes from persistence.

Focus on the field of ball valve for 30 years

The company has 8 national patents and 2 national invention patents. It is the national standard drafting unit of Eccentric Hemispherical Valve (GB/T26146-2010), the industry standard drafting unit of Technical Conditions for Valves for Coal Chemical Plants (JB/T12797-2016), the industry standard drafting unit of V-shaped Ball Valve, and the industry standard drafting unit of Insulation Jacket Valve. It has CAD,CAM development, design and manufacturing and ERP enterprise resource planning management system, it has 60 sets of machining centers, numerical control machine tools and metal cutting equipment, 30 sets (sets) of physical and chemical, non-destructive testing, spectral analysis and valve comprehensive performance testing equipment. The company has passed TS, EU CE, safety production standardization, ISO9001 international quality system certification, ISO14001 environment system and OHSAS18001 occupational health and safety management system certification.

product series

Covers 5 categories, a number of special valves

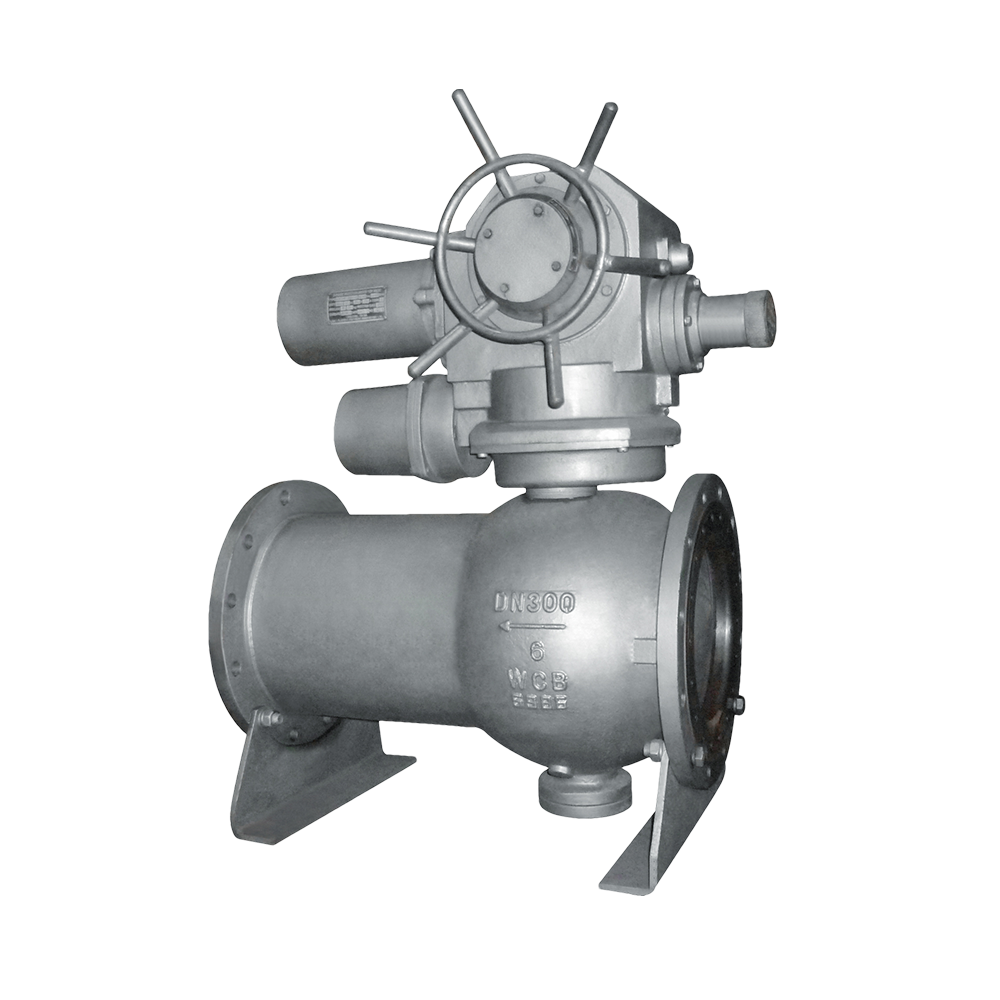

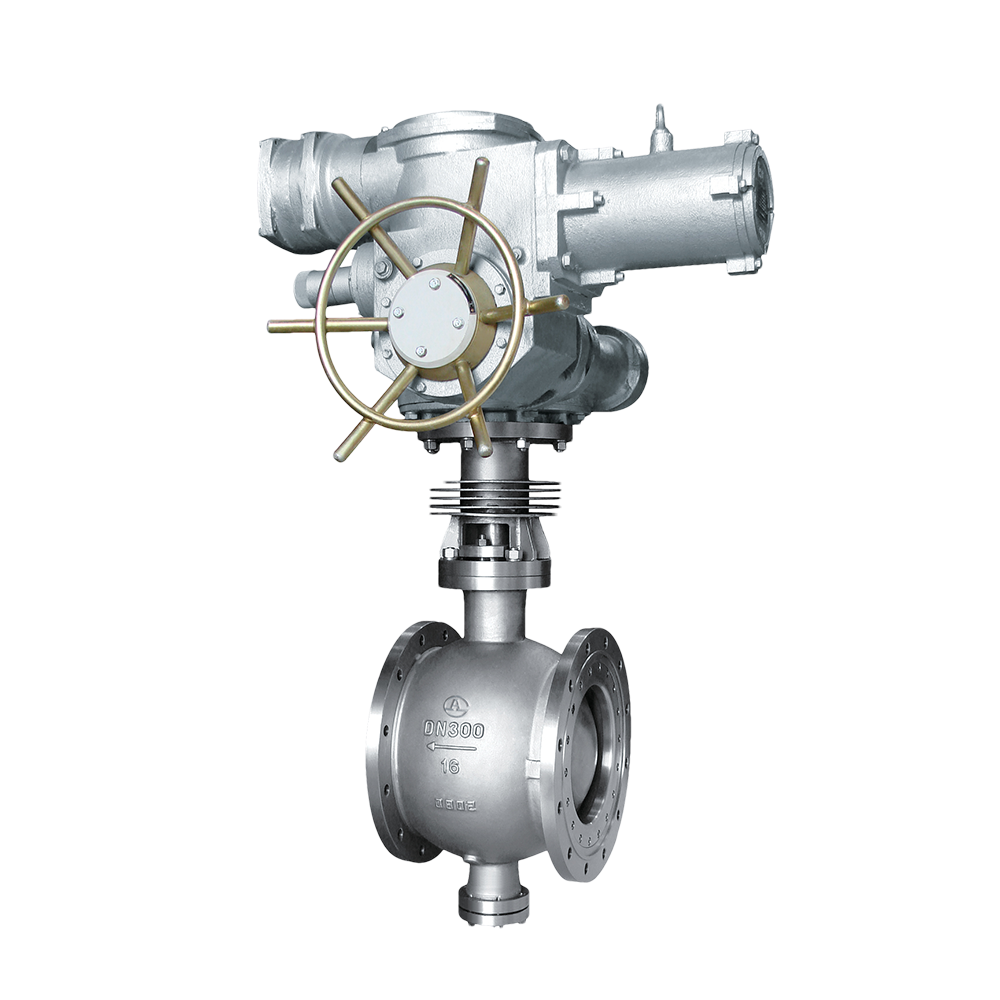

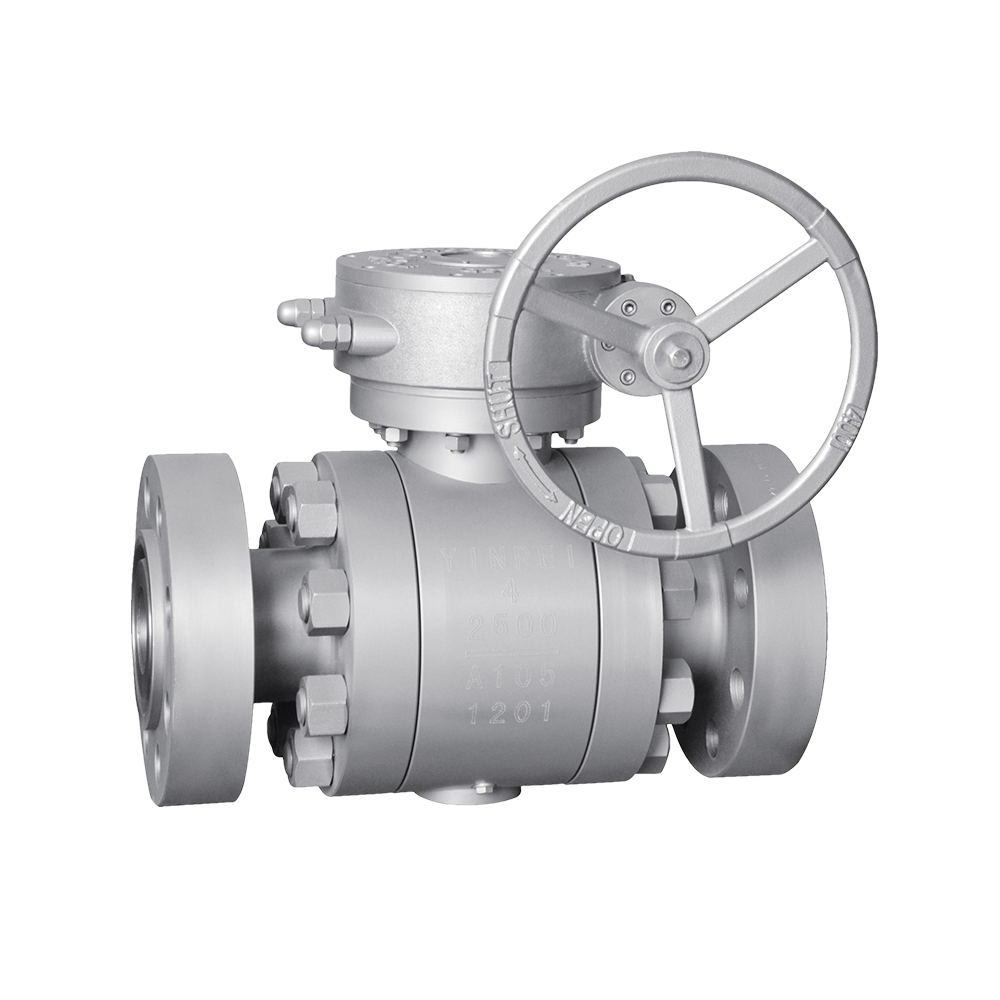

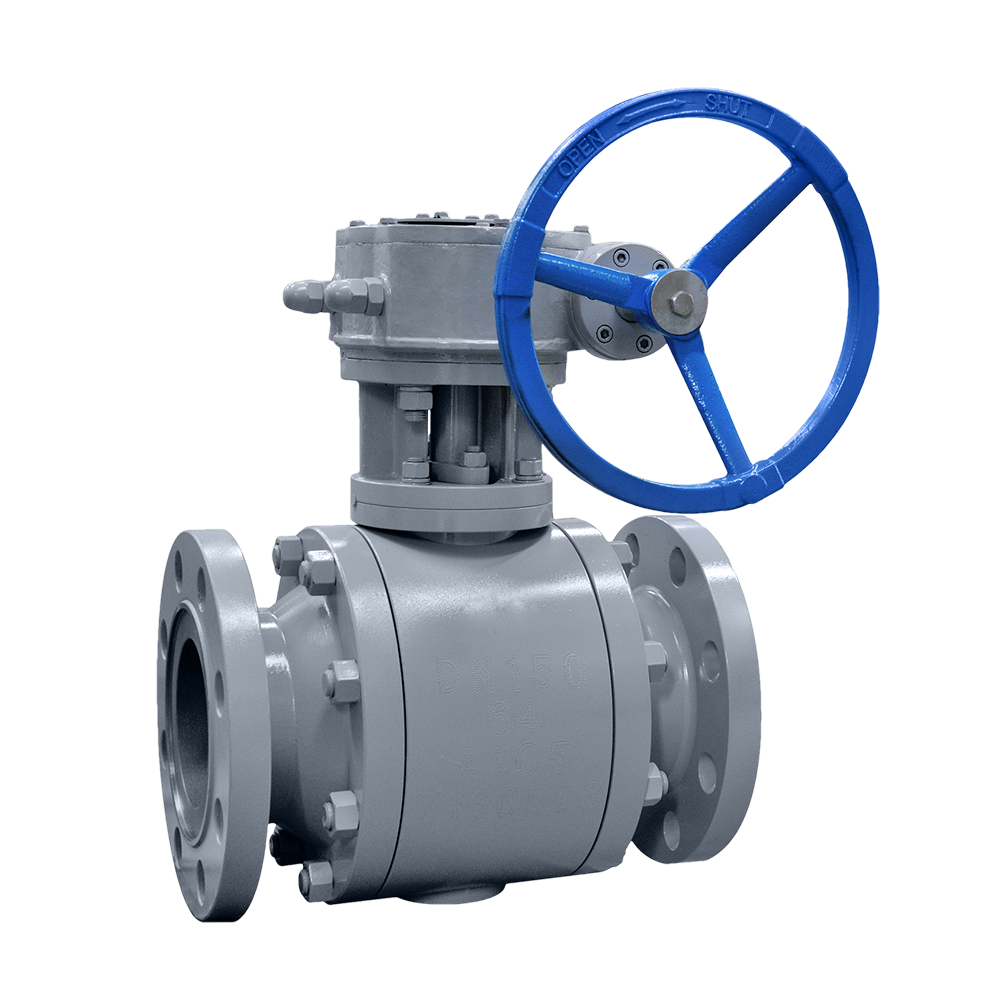

O-Ball valve

C-Ball Valve

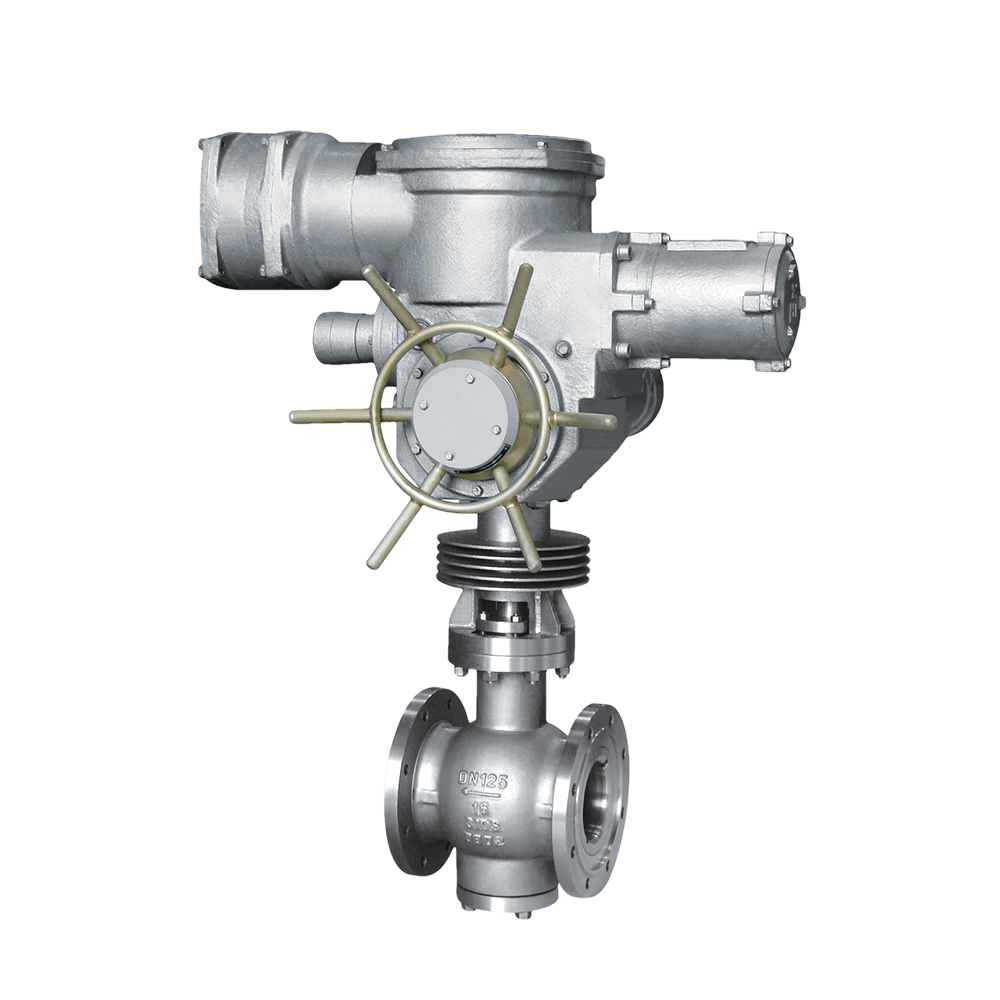

V-Ball Valve

Jacketed Ball Valve

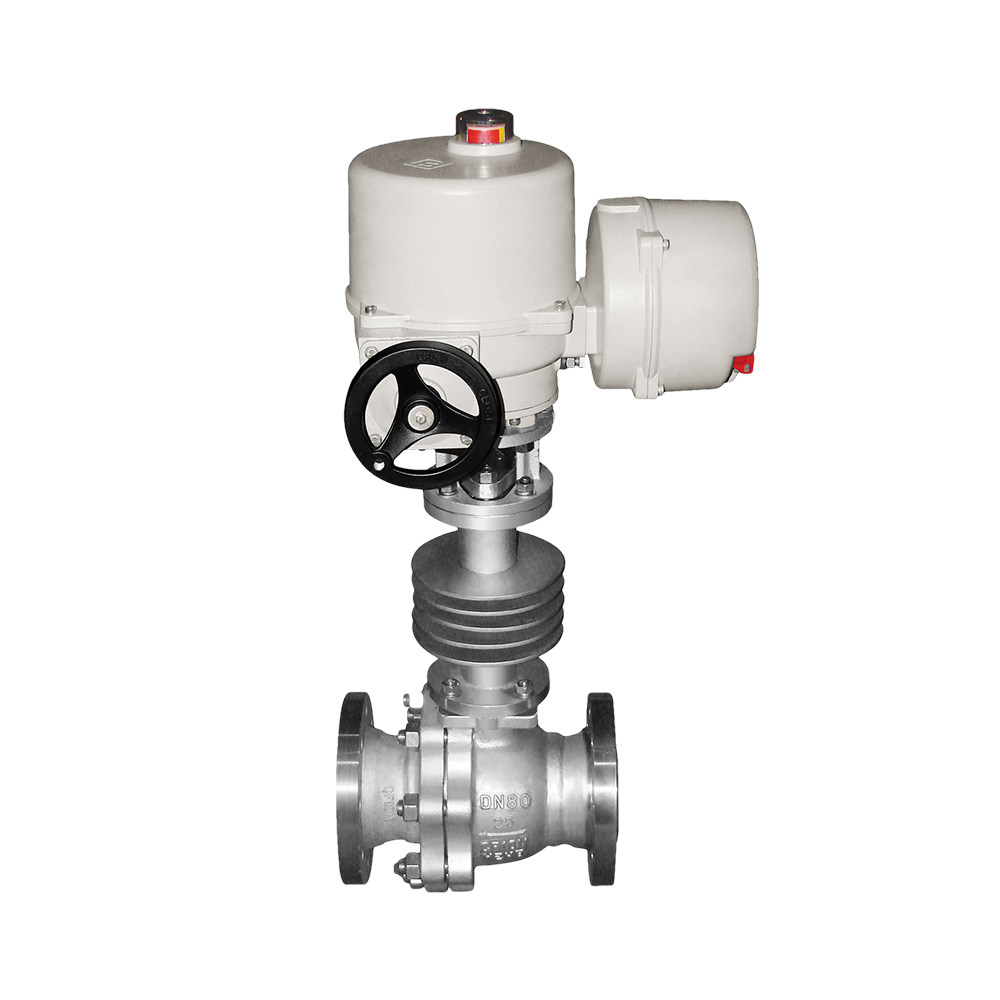

Cryogenic Ball Valve

High Temperature Ball Valve

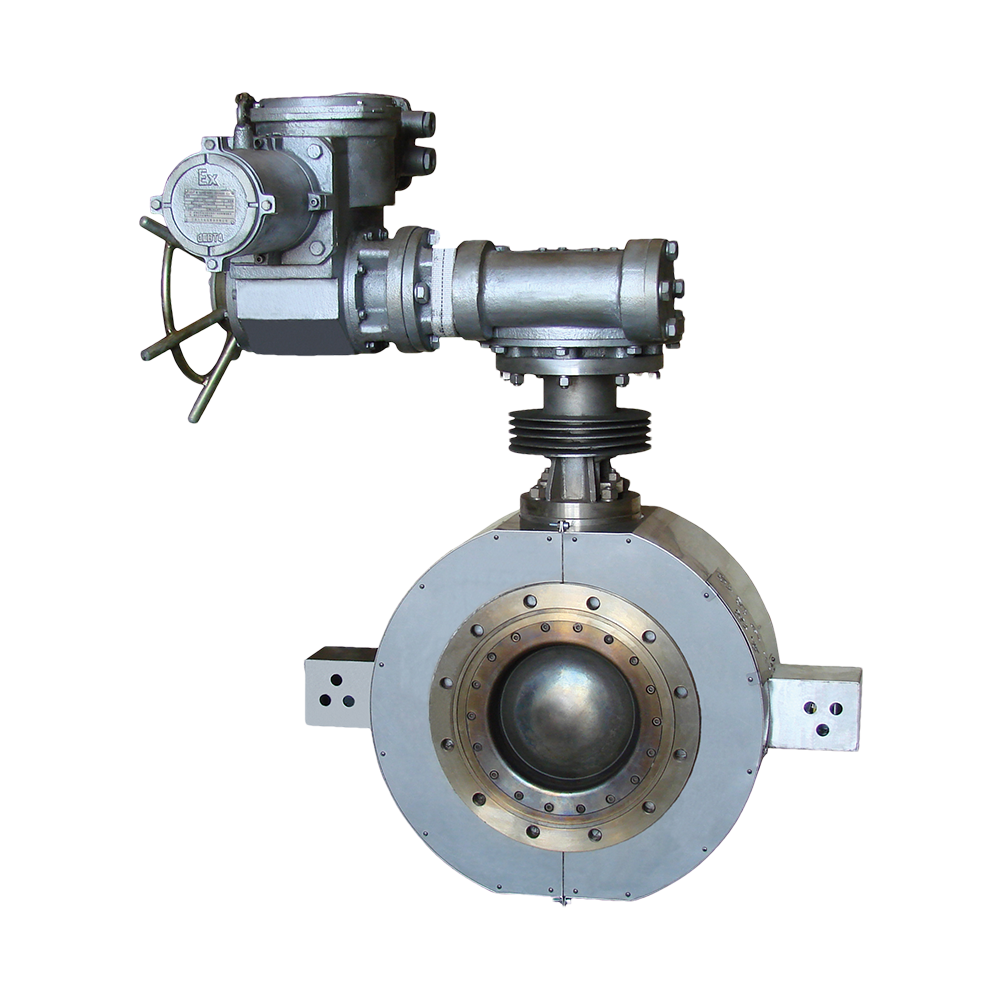

Orbit Ball Valve

AOGONG

30 years of deep cultivation in the field of ball valve

From standards to standards.

Products are widely used in petroleum, chemical, natural gas, electricity, Metallurgy, papermaking, sewage treatment and other industries

Oil industry

Chemical Industry

Natural Gas Industry

electric power industry

metallurgical industry

Polysilicon industry

News

What is the difference between high temperature ball valve and ordinary ball valve

Material is not the same, high temperature ball valve generally used alloy body, this material high temperature, corrosion resistance; ordinary steel ball valve and copper ball valve is only rust, while the thermal deformation is relatively large. The main difference between 1. high temperature ball valve and normal temperature ball valve manufacturing process is different. 2. the material is not the same, high temperature ball valve generally use alloy body, this material high temperature, corrosion resistance; ordinary steel ball valve and copper ball valve is only rust, while the thermal deformation is relatively large.

04-26

Several valves commonly used in chemical production and their use

The four kinds of valves introduced here are the most commonly used shut-off valves in chemical industry. Their main function is to connect and cut off the medium circulation in the pipeline. Although some of them can play a role in adjusting the flow rate, they cannot be completely used as control valves. 1. ball valve This is a very comprehensive valve, improved in the plug valve and valve center ball rotation control opening and closing, flexible action, small size, light weight, medium flow resistance is small, good sealing effect.

04-26

Working principle of track ball valve

The working principle of the track ball valve is as follows: 1) Opening process 1. In the closed position, the ball by the valve stem of the mechanical pressure, pressed on the seat.

04-26

What are the advantages and how to classify the ash unloading ball valve?

Ash ball valve is evolved from the globe valve. It has the same rotary 90-degree lifting action, except that the cock body is spherical and has a circular through hole or passage through its axis. The ratio of the spherical surface and the channel opening should be such that when the ball rotates 90 degrees, the spherical surface should be present at the inlet and outlet, thus intercepting the flow. 1. role The working principle of the ash unloading ball valve is to make the valve unblocked or blocked by the rotary valve. The pneumatic ball valve switch is light, small in size, can be made into a large diameter, reliable in sealing, simple in structure, convenient in maintenance, the sealing surface and the spherical surface are often in a closed state, and are not easily eroded by the medium. It is widely used in various industries.

04-26

Structural characteristics of orbital ball valves

Structural characteristics: The ball valve has the advantages of small size, compact structure, convenient use and installation, and long life. With no friction sealing structure design, the valve is opened when the ball rotates before leaving the sealing surface after rotation, the contact between the sealing surface without scraping effect, prolong the use of the valve. When the valve is closed, the mechanical wedge extrusion seal is applied downward by the valve stem to obtain a tight sealing effect. With the change of medium temperature, the stress of the pipeline will not affect the mechanical properties and sealing performance of the valve. When the valve is closed, the ball in the rotation process, the ball and the valve seat to maintain a certain space, due to the rotation of the ball flow will be reduced, the flow rate increases so as to achieve the role of flushing the sealing surface, so that it remains clean.

04-26

According to the orientation of the valve core into the valve body, the eccentric semi-ball valve is divided into "side-mounted" and "top-mounted" two structural forms. These two structural forms have their own advantages and disadvantages, which are briefly described as follows. 1, "side-mounted" compact structure, body close to circumferential symmetry, the overall rigidity is good. The "top-mounted type" due to the existence of the mouth, greatly destroyed the body symmetry of the body of revolution, in the pipeline axial force (including the medium force and sealing side effect force), will produce asymmetric elastic deformation, resulting in uneven deformation of the valve seat, so that the seal pair anastomosis reduced, resulting in leakage. Therefore, in the higher pressure, the larger diameter of the valve, the use of "top-mounted" is not appropriate.

04-26